Contents

MDF wood is amongst the cheapest wood options on the market, compared to varieties such as plywood. Yet, when you pick the right types of MDF, they offer great advantages. Their smooth surface makes them ideal for painting, while their consistency eliminates any voids and splinters.

MDF board is also a perfect wood for creating decorative edges using tools such as wood routers. In this in-depth, you will learn everything there is to know about MDF and the different types of fiberboards available on the market.

What Is MDF?

MDF refers to medium-density fiberboard made using hardwood or softwood fibers to form panels. Common types of wood used to make MDF include pine. MDF board tends to be denser than plywood. However, it has a soft and smooth surface that makes it an excellent decorative wood.

MDF comes with several advantages compared to other wood. MDF board is consistent in size, strength, and shape. It also offers stable dimensions with less expansion compared to natural wood. Additionally, MDF wood is an excellent option for woodworking and furniture making is its ability to take glue and paint well.

MDF board is also quite flexible. However, it has a limitation of poor screwing support due to its high tensile and stiff nature. In poor quality, MDF boards can also easily swell and break when saturated with water.

How Is MDF Made?

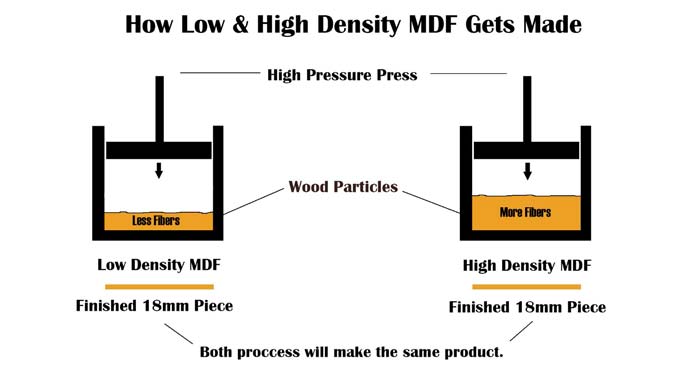

MDF board is made using softwood or hardwood residuals. The wood is first shredded in a chipper, turning it into wood chips. Next, the wood is washed to remove lignin and other impurities. Using a defibrator, hardwood or softwood is mixed with wax and a resin binder at high temperature and pressure to create panels.

When creating the panels, the little wood chips are sorted based on size. The finest fibers go to the outer face while the larger ones remain in the core. The finished product produces a stable and solid board with fine and even texture. Additionally, MDF boards come in varying thicknesses, ranging from 3 to 30 mm.

When shopping, you will come across different types of MDF boards. These include ultralight boards, moisture-resistant boards, and fire retardant boards. The choice of MDF board you go for simply depends on what works out for you for woodworking.

Types of MDF Wood

Here are the different types of MDF board wood:

Hardboard

Hardboard is made using higher pressure and temperature compared to standard MDF. In turn, this gives this type of wood an ultra-strong and hard finish, as its name suggests. However, it doesn’t become very thick. It has a smooth and rough face on the exterior, making it ideal for drawer bottoms, flooring, and rear parts of furniture.

Waterproof MDF

Also known as moisture-resistant MDF, waterproof MDF comes in a sheet made using compressed wood fibers combined with water-resistant resin. It also features high internal bond strength to repel further water and moisture. Thanks to this durable design, waterproof MDF is ideal for making skirting boards and window boards.

Colored MDF

As the name suggests, colored MDF refers to normal MDF that is colored. These types of MDF are versatile as they come in different color options to give a designer or builder more variety. Their versatility also allows them to be easily fabricated with standard woodworking tools.

Normal MDF

Also known as regular MDF, this type of MDF represents the common type. It is simply made using refined wood chips put together at high temperatures and pressure. These types of MDF boards tend to be denser than plywood and have lower elasticity.

This, in turn, makes them quite stiff. Using power tools like wood routers, you can use this type of MDF to make anything from furniture to cabinets, flooring, speaker boxes, and even decorative wood items.

MDF with Melamine on Both Sides

This type of MDF board tends to be thinner than regular MDF, about 5mm (50% thinner. However, you can still find it in different colors and thicknesses. You can also find this type of wood is waterproof and non-waterproof finish.

The nitrogen-based compound, melamine, cover the MDF core to give it a flat and smooth surface. Additionally, melamine-covered MDF tends to have dimensional stability, high density, and is easier to process. Because it’s covered with a smooth surface on both sides, it is typically used for decorative furniture.

MDF with A Beech Veneer

MDF covered with beech veneer simply refers to MDF boards manufactured using high-quality beech wood veneers firmly attached to medium density fiberboards. Typically, the MDF panels are covered with about 0.5mm to 16mm of veneer coating on both sides to improve their aesthetics. This style of veneering can be done using different wood types.

However, beech gives the wood a pale pink to creamy reddish light brown color. The type of beech wood used is typically steamed or European beech. This design provides the MDF board with a fine silky texture with tight uniform grain. In turn, it makes an excellent option for furniture making.

Post-formed MDF

Post-formed MDF refers to MDF boards with a curved edge on the front before a laminate is attached. This type of MDD board is typically used for interior doors, furniture doors, and even kitchen countertops.

Uses of MDF Board on Woodworking

The number one advantage of using an MDF board is, of course, its smooth, paintable, and durable surface. Additionally, the MDF board is favored for its affordability compared to plywood. Thus, it has multiple uses. Since it comes in different types, it gives you a wide range of options to pick from based on the design and finish you like. Some of the common uses of MDF board in woodworking include:

- Furniture, chest, and shelf making

- Doors and door frames

- Decorative projects using woodworking tools such as routers

- Flooring

- Wainscoting

Processing MDF Board

Unlike other wood types, MDF is quite neat and without any grain due to its manufacturing process. It also features a homogenous design, making it easy to cut through and even mill. However, unlike plywood, it does produce a lot of dust.

Additionally, MDF is reported to contain urea-formaldehyde. Thus, when cut or sanded, it may result in the inhalation of harmful particles. So, before you whip out your power tools such as a wood router or something similar and start working on them, you need the ideal protective gear. Make sure you have on safety glasses and a mask! Additionally, working with putting together MDF using wood glue is easy.

However, to prevent making a mess, you need the right equipment. For one, make sure you have a proper workbench and the right power tools. The smooth surface of MDF makes it easy to paint on. However, you have to refrain from staining it.

Because it has no wood grains for aesthetics, MDF will simply soak up the stain and ruin the quality. Additionally, you have to pay attention to the design of your woodworking projects. Due to its small particles, MDF doesn’t do an excellent job when it comes to holding a lot of screws.