Contents

If you want to enhance the look of your living space or garden, there are plenty of ways you can do so. One easy way is to DIY build or decorates your furniture – whether you want to add some fabric to your chairs or craft your own table.

The guide below can walk you through joining wood planks for a tabletop. Whilst different people opt for different sizing dimensions and designs, the guide offers standard know-how and principles for building your tabletop. Happy crafting!

Tools And Materials

Here are the tools and materials required for the task:

[su_spoiler title=”Required Tools for this Project:” open=”yes” style=”simple” icon=”plus” anchor=”” class=””]

[su_list icon=”icon: arrow-circle-right” icon_color=”#4f8901″]

[su_row class=””]

[su_column size=”1/2″ center=”no” class=””]

- Wood planks

- Thickness planer

- Measuring tape or stick

- Pencil

- Jigsaw

- Wood glue

[/su_column]

[su_column size=”1/2″ center=”no” class=””]

- Secondary wood clamps

- Wood router

- Belt sander

- 220-grit sanding paper

- Wood stain

[/su_column]

[/su_row]

[/su_list]

[/su_spoiler]

Step-By-Step Instructions

The wood plank joining and table-making process follows a couple of steps. These include:

Step 1 – Source For And Choose The Ideal Wood Plank

- The first step is to pick your wood plank. You have to pay attention to this step as the wood plank you go for will determine the quality of your tabletop. Opt for wood planks such as cherry wood, walnut, hickory, or pinewood – based on your budget and design needs. For example, cherry wood works best for formal dining room tables whilst hickory works for rustic designs. Pine on the other end is an excellent budget wood.

- When you are picking your wood, look out for any defects or warps. Ideally, you want your wood plank to be flat with no twists or bows. Remember the wood planks are going to be joined together so you want the material to be flat! Furthermore, as you bundle up the wood planks look at their texture and grain pattern to ensure they are similar. This helps the table top to look neat once you join them. Lastly, make sure the wood is dry to allow them to hold better when you apply glue.

Step 2 – Prepare The Wood Planks

- If you buy your wood in a home improvement store, chances are they will have the same thickness. Alternatively, you can use a thickness planer to mill the pieces to get them to the same thickness.

- After milling your wood planks, check to ensure the grain pattern is the same. If any of the pieces need more work, pull them out and run them through the mill again.

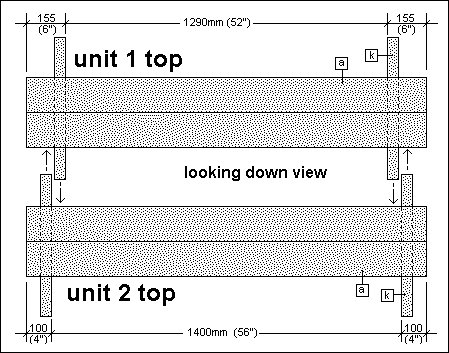

- Before you start to join the wood planks, make sure they are in the dimensions you want. If not, use a measuring tape or stick to measure the size you want and mark the wood using a pencil. Then, use a jigsaw or router to cut them.

Step 3 – Join The Wood Planks

- You can choose from a myriad of different plank joining methods. Some of the common methods you can go for include:

- Side to side joining – This process involves aligning the wood pieces on the edge and then, connecting them together by applying glue between them. You must ensure the wood glue is strong.

- Using a jig or joiner – You can opt for a dowel jig or biscuit joiner to reinforce the wood joints. In this case, you insert the wood with glue and join the edges. This process is particularly ideal if you want to toughen and strengthen your tabletop. Using a biscuit joiner, you can add biscuit joints (created by joining one or more biscuits in between the wood planks). Thus, in addition to using wood glue, the biscuits help to add more strength to the joints.

- Batten process- Alternatively, you can run battens on the bottom of the tab. This process involves at least 4 wood pieces placed underneath the structure (like plywood) to hold other wood pieces and prevents the entire tabletop from moving. The planks are, then, held together using glue and hide the plywood underneath.

- When you decide on the joining method, the actual joining principle remains the same. In this guide, we used side-to-side gluing. When joining the wood planks, join them in pairs of two or three at a time to prevent creating a mess and to ensure the wood are joined seamlessly.

- Use a wood clamp to carefully clamp the wood plank pieces together – ensuring they are neat and evenly held. During the clamping process, it is common for the wood to move around. Thus, you have to pay extra attention to the clamping process – secondary clamps do a better job at the task. When you clamp down the wood plank pieces, make sure you balance out the pressure. Too much pressure can easily make a plank snap or slide.

- When you are done with the clamp, use a wet piece of cloth to wipe out excess glue that may be on the wood surface or dripping. As you wipe, frequently wet the cloth, squeeze out well, continue wiping and repeat the steps. Make sure you remove as much glue as possible to prevent it from forming a film that may cause difficulty during the sanding process.

- After wiping off excess glue, let the wood planks dry properly, and then, examine the joints to ensure they are properly joined.

- If everything is fine, repeat steps 5 to 9. As you add the next batches of wood planks, you can add them to the first batch by pre-gluing the two to three pieces first or by simply building them up from the existing batch into a large tabletop of joined planks. However, for the second option, you need to invest in extra secondary clamps.

Step 4 –Sand And Finish Up The Surface

- The next step is to finish up on the tabletop. If you want to go for a standard table design, you can proceed with the sanding process. If you want a few designs on your tabletop, this is the time to pull out your wood router. Use the wood router to carve out the designs you want.

- Once done, use a belt sander to even out the surface, and once done, use 220-grit sandpaper to remove any scratches or defects on the wood.

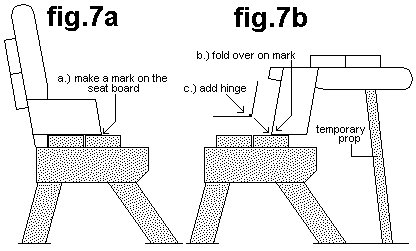

- To finish up your tabletops, you can opt for a choice of two methods. First, you can opt to use a stain and polyurethane wood finish and stain to coat the surface, protect it from scratches and water damage. Additionally, it gives the wood a glossy, smooth finish. Alternatively, you can opt for an oil and wax finish. Whilst an oil and wax finish makes it easier to repair, if you need to, it can be quite time-consuming. To prevent the need for repairing your tabletop from time to time, you can design it to reduce warping. In this case, you can opt for a breadboard ends method – by creating space between each wood panel and attaching the edges of another wood plank using glue. Or, you can opt to connect the wood planks with figure 8 fasteners and buttons.