Contents

Materials and post installation

| Materials to use | |

| 100×100 (4×4) posts | 2400 (8ft) long. Can either be sawn (rough) or dressed (smooth). Must be of stock suitable for in ground applications. Posts should not be more than 2400mm (8ft) apart. |

| 100×50 (2×4) rails | Can either be sawn (rough) or dressed (smooth). Must be of stock suitable for exterior use. 4800mm (16ft) lengths will span 3 fence posts. |

| 150×25 (1×6) fence boards | Can either be sawn (rough) or dressed (smooth). Must be of stock suitable for exterior use. Fence boards should not touch the ground. |

| 25×25 (1×1) stops | Can either be sawn (rough) or dressed (smooth). Must be of stock suitable for exterior use. To hold “sandwich” the lattice in. |

| 100mm (4″) galvanized nails | To fix the rails to the posts |

| 60mm (2 1/4″) galvanized flat head nails | To fix the fence boards to the rails |

| 50mm (2″) galvanized nails | To fix the stops against the lattice to the posts and rails |

| Lattice | Can be made to size or purchased in lager sheets and cut on site. Usually either a square or diagonal profile with various size gaps. For more info about lattice Click Here |

| Concrete | To concrete the posts into the ground |

Installing the Fence Posts:

(1) Determine the fence line and mark it out with a string line. Continue the string line 600mm (2ft) past each end of the fence line and tie each end to stakes hammered into the ground. Ensure the string line is taut and not touching the ground at any part.

(2) Push two small pegs into the ground marketing the center position of the two end posts.

(3) Next, peg the position of the intermediate posts along the string line, ensuring all pegs are equal distant apart and not exceeding 2400mm (8ft). Offset all pegs 50mm (2″) in from the string line. This is to establish the center of the post, as the posts are 100mm (4″) wide.

(4) Remove the string line and dig the post holes, 250mm (10″) square x 700mm (28″) deep. The pegs mark the centers of the postholes.

(5) When all holes are dug and cleaned out, replace the string line to its original position, checking the string line is not touching the ground at any part.

(6) Make a mix of concrete in a wheelbarrow at a ratio of 3 gravel, 2 sand and 1 cement. Add clean water and mix to a uniform consistency until wet enough to fill around the posts, yet stiff enough to hold the posts upright without the need of supports or braces. Of course you will need a wind free day. Carefully shovel 100mm (4″) of concrete into the bottom of every hole.

(7) Starting at one end, commence putting the posts in the holes. Using a plumb level against two adjacent sides, check that each post is plumb (vertical), and almost, but not quite, touching the string line.

(8) Fill hole with concrete to within 50mm (2″) of ground level. Check again the post is plumb and not quite touching the string line. Because of the depth of the hole, the concrete will support the post without the need for bracing, but not on a very windy day. Continue until all posts are concreted in.

This method saves a lot of time and lumber without the need of bracing the posts, check the posts again for plumb (vertical) and that they are not touching (but close to) the string line. Leave until the concrete cures.

The rails, the boards and the lattice

Fixing the rails:

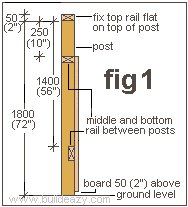

- Fix a string line to both of the end posts 1800mm (6ft) above ground, and mark all the intermediate posts at string line height.

- Trim the top of the posts on the height marks.

- Nail the top rail flat on top of the posts (fig 1). One rail should span two sections (3 posts).

- Cut, fit and nail middle and bottom rails in between posts, heights as shown in (fig 1).

Fixing the fence boards:

- Fix the first board at the start of the fence line with the top of the board flush with the top of the middle rail (The bottom of the board should be 50mm (2″) from ground). Use a plumb level to ensure the board is plumb (vertical) and nail in place using 60mm (2 1/4″) galvanized flathead nails, 2 at each rail.

- Continue by placing another board against the first and make the top of the board flush with the top of the middle rail.

- Nail in place and repeat that action until all boards are in place.

- Check, as you are going, about every 10th board with a plumb level for plumb (vertical), and make any necessary adjustments.

Fitting the Lattice:

Note: Most lattice manufacturers make lattice sizes to order. Bigger sheets can also be purchased at most building supply stores, this is usually the less expensive option and the lattice can be cut to suit on the job.

- Measure between the top and middle rail and between the two posts in each section and deduct 5mm (1/4″) from the measurement to allow for play. For example, if the exact measured size of a particular section is 2200mm (88″) wide x 250mm (10″) high, then the lattice size for that section would need to be 2195mm (87 3/4″) wide x 245mm (9 3/4″) high.

- Measure the same way for every section and order or cut the lattice of your selected profile.

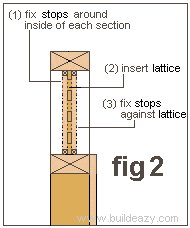

- Insert the lattice as shown in fig 2 and follow steps below.

(1) Firstly, fix 25mm x 25mm (1″x1″) square stops around the inside of the frame to one side only.

(2) Insert the lattice.

(3) Fix the stops against the lattice on the other side (see fig 2).