Introduction

This section explains how to install the most common and basic forms of open shelving, consisting of either solid lumber boards or specifically manufactured shelving boards that sit on brackets cantilevered from a lumber framed wall.

Three widely used bracket systems are:

- wooden braced brackets fixed to vertical battens

- L-shaped metal brackets fixed to the wall studs

- Metal brackets that clip into a slotted metal, hollow square-section that is fixed upright to the wall stud.

The procedure involves: deciding on the most suitable bracket type; determining the position and height of the shelves; finding the wall studs; securing the upright battens and/or brackets, and placing the shelves.

Bracket options

Three widely used bracket systems are:

- Wooden braced brackets fixed to vertical battens

- L-shaped metal brackets fixed to the wall studs

- Metal brackets that clip into slotted metal strip fixed to the wall stud.

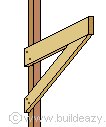

Wooden brackets fixed to vertical battens

- A wooden shelf bracket comprises of a horizontal piece of wood screwed or nailed to the side of a vertical batten that is fixed to the wall.

- The horizontal piece of wood is propped by another piece of wood fixed to the underside of the front of the horizontal member and angling down to the vertical batten.

- A wooden shelf bracket can be made out of varying size wood such as 45×20 (3/4″x 1-1/2″) or 65×20 (3/4″x 2-1/2″) or bigger.

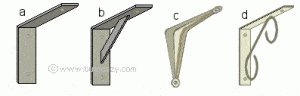

L-shaped metal brackets fixed to the wall studs

- L-shaped metal brackets come in varying sizes and styles, and achieve maximum strength if screwed directly through the wallboard and into the wall stud.

Summary of appropriate weights for each brackets are:

(a) Metal plate bracket: depending on the thickness of the plate, medium to heavy strength.

(b) Metal plate braced bracket: heavy strength.

(c) Pressed-steel bracket: light to medium strength.

(d) Ornate bracket: depending on thickness of metal and brace, light to heavy strength.

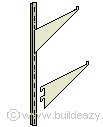

Metal brackets that clip into slotted metal strip fixed to the wall stud

- This system achieves maximum strength if the vertical slotted metal strips are screwed directly through the wallboard into the wall studs. The metal strips come in varying lengths as do the brackets that slot into them. This is probably the easiest system to install and the brackets are also adjustable, however it is also the most expensive.

Find the studs

- Determine the desired shelf position and then seek the possible fixing members. Although fixing uprights or shelf brackets through the wallboard into the wall studs is preferred, it is not always possible and in some instances the uprights or shelf brackets may have to be fixed to the wallboard using appropriate fasteners.

What is a stud?

A stud is a vertical framing member used to construct walls to which exterior or interior covering material may be attached. A standard house wall stud is approx 45mm (1-1/2″) thick.

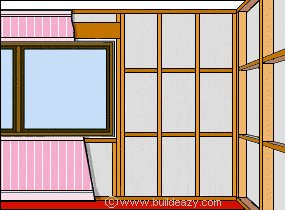

Where are the studs in a wall?

Studs are placed for required strength and also for the fixing of 1200mm (4ft) wallboards. Where possible, studs are usually spaced apart 400mm (16″) or 600mm (24″) from center to center. There is also usually a double stud thickness at the side of a window, door or opening, and also a stud at the corner of any room.

How are the studs found?

Studs can be found by tapping along the wall and listening for a change in sound.

Do the uprights or brackets have to be fixed to the wall studs?

Uprights or brackets can also be fixed to horizontal blocking or even to the wallboard using the appropriate fasteners. However fixing uprights or brackets directly to the center of the wall studs (through the wallboard) will ensure maximum strength.

Fix the verticals, the brackets and the shelving

- It is now simply a matter of screwing the upright battens and/or brackets through the wallboard into the wall studs and placing the shelves. Most clip-in brackets have a little upturned lip at the front, thus keeping the shelf in place. Angle brackets generally have pre-drilled holes to allow for screws to hold the shelves in place. With timber brackets, the shelves can be fixed with screws down through the top of the shelf (drill a hole first) into the bracket.

- A light load for 250mm (10″) wide x 20mm (3/4″) thick solid board shelf is 15kg per meter length (10lb per ft length).

- A medium load for 250mm (10″) wide x 20mm (3/4″) thick solid board shelf is 30kg per meter length (20lb per ft length).

- A heavy load for 250mm (10″) wide x 20mm (3/4″) thick solid board shelf is 45+kg per meter length (30+lb per ft length).

- Large books are considered a heavy load.

- A solid 20mm (3/4″) thick solid board shelf should not span more than 750mm (30″) if designed for heavy load.

- Note that the above information is a guide only.